Loading...

Backflow testing must be conducted by a certified backflow assembly tester at the time of installation, repair, or relocation of the device, and at least on an annual schedule thereafter. We provide inspection, testing, repair, and replacement services for Boise, Meridian, Star, Eagle, Kuna, Middleton, Melba, Parma, Fruitland, Avimor, and Hidden Springs. Our testing equipment is calibrated yearly to maintain a high level of accuracy. We will perform backflow testing, tag the device, and submit a copy of the test results to you by email as well as to the water purveyor on your behalf. We also keep test results on file for several years. If your backflow preventer does not pass the backflow testing procedure, we will advise you on the necessary steps to get it to pass. This could be as simple as cleaning the working parts of the assembly, replacing worn parts, or in extreme cases, replacing the device. No repair work will be performed without your permission after discussing the options and estimating the cost of the repair or replacement.

The Maintenance Shop has repaired, replaced, and installed backflow preventers for over 20 years in the Treasure Valley, and have built a reputation of honest and quality work.

More than half of the repairs we do each year on backflow preventers and vauum breakers are from freeze damage. Either the devices were not blown out properly, test cocks and shut-off valves no set to the winterized configuration, blowout was done after they froze, or they were not blown out at all. The Maintenance Shop has done over 50,000 sprinkler blowouts, so be sure to sign up with us for your next one.

The pressure vacuum breaker may be used to protect against either a pollutant or a contaminent, but it may only be used for backsiphonage. This assembly must be installed at least 12 inchces above all downstream piping and outlets, and can be under continuous pressure.

The Pressure Vacuum Breaker will discharge water through the air inlet at the top until it is pressurized.

We see Pressure Vacuum Breakers quite often on sprinkler systems in the Treasure Valley. We can test, repair, or replace these when the need arises.

The double check valve assembly may be used to protect against a direct or in-direct cross connection, and may be used to protect against a pollutant (non health hazzard) only.

Double check valve assemblies are another backflow device found on many sprinkler systems in the Treasure Valley. However, they are no longer allowed for sprinkler systems in all but four states; including Idaho. Existing units, (installed before the law change on March 28, 2018) can stay in place as long as they pass the annual backflow test. As licensed backflow testers we will no longer be able to install these devices on sprinkler systems, but we will test and repair the double check valve assembly already installed until parts are no longer available. If the backflow preventer cannot be repaired, it will need replaced with either the PVB or RP.

For more information regarding the code change for double check assemblies click here.

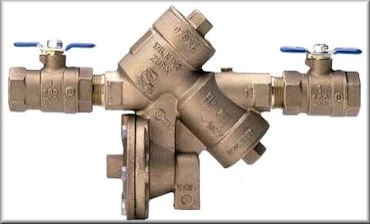

The reduced pressure principle backflow assembly contains two check valves and a relief valve.

The relief valve can sense if backflow is beginning to occur or if one of the check valves is failing and release pressure from the region between the check valves. This will either correct the hydraulic condition or it will continue to discharge water from between the check valves in order to keep contaminated water from moving upstream into the potable water supply.

Since the RP is designed to prevent backflow even if one or both of the check valves fail, it is a very reliable means of backflow protection. The reduced pressure principle assembly may be used to protect against a pollutant or a contaminant and may be used to protect against a direct or indirect cross-connection.

This type of backflow assembly is ideal for sprinkler systems, and we do see them at many commercial sites and parks, and on "dual" systems that have the ability to run city water or pressurized irrigation. These are also the only ones that can be installed on a sprinkler system where a PVB will not meet code requirements. We can test, repair, replace, and install this type of backflow assembly.

The spill resistant pressure vacuum breaker is very similar to the pressure vacuum breaker and also may be used to protect against either a pollutant or a contaminent, but it may only be used for backsiphonage. This assembly must also be installed at least twelve inches above all downstream piping and outlets; and can be under continuous pressure.

We see spill resistant pressure vacuum breakers occasionally on sprinkler systems in the Treasure Valley, but most of the time they will be used inside a building where it would be undesirable for water to discharge from the unit when it is turned on as the pressure vacuum breaker does.. We can test, repair, or replace these when the need arises.

An atmospheric vacuum breaker is designed to protect against a non-health hazard (i.e., pollutant) or a health hazard (i.e., contaminant) under a acksiphonage condition only.

A shutoff valve immediately upstream may be an integral part of the assembly, butthere shall be no shutoff valves or obstructions downstream. The assembly shall not be subjected to operating pressure for more than 12 hours in any 24 hour period.

The atmospheric vacuum breaker cannot be tested. The only reason we are showing it here is because we see these still on sprinkler systems on rare occassions, and they are illegal. If you have one of these on your sprnkler system, contact us on how we can replace it with a proper backflow prevention device.

With so many homes, businesses, restaurants, churches, etc., in the Treasure Valley, it can sometimes be difficult getting a sprinkler blowout before a freeze.

Click on the image to find out how you can easily prevent your backflow from damage if the temperature drops below freezing and stays there for a while.